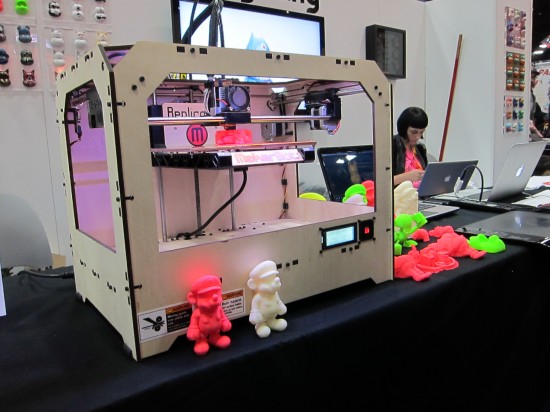

MakerBot Replicator and DIY Designer Toys?

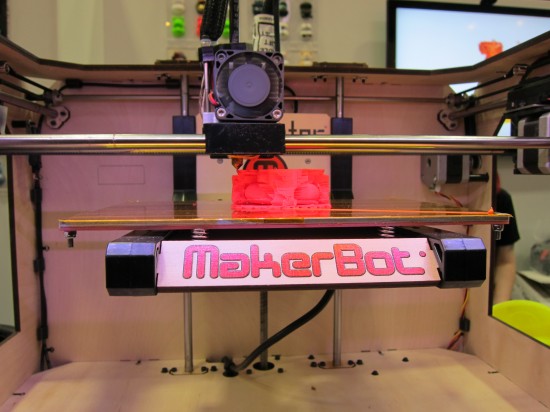

3D printing is getting closer to being a reality for amateurs and in-home use. The MakerBot folks were on hand at Comic-Con to demonstrate their newest machine, The MakerBot Replicator, priced at $1,749. They’re billing it as the “ultimate personal 3D printer,” and it allows makers to start printing objects (in multiple colors, as big as a loaf of bread) right out of the box.

Digital printing aficionado, Dave Bondi, whipped up his Akashi, a custom Omi and designs by Joe Ledbetter and Ron English while fans watched at Munky King’s booth. With a MakerBot Replicator, you can make and multiply your own creations or choose thousands of others from growing online databases and communities.

In distilled essence: MakerBot allows you to think of an object you need (“I just cracked my iPhone inCase case again!”) or come up with your own unique idea (“Ron English-style vinyl toy mascot for Kashi cereal”), bring it into 3D physical reality and multiply it. Whoa.

Collectors of designer toys have been tepid on this technology, but consider the fact that the Replicator lets you print in either ABS (like LEGOs) or PLA (a bio-material made from corn). Not only that, but you can easily replace broken parts and even mint your own accessories. Imagine if your basic ink jet printer laid down fine powder and glue instead of ink and moved vertically instead of horizontally, and you’ll have a simplified understanding of “additive manufacturing”. Vinyl is so Toy Art 1.0.

What do you think about seeing art toys made on-demand? Consider it a modern counterpart to Rotofugi’s Roto-a-Matic (but with you in the designer’s position) or a minimal MAQET (but where you control the shape).

Here’s Bondi showing off his neon green, 3D-printed custom Omi. Click through for a couple closeups of 3D prints that you might recognize…

See also Wired’s New 3D Printers That Don’t Suck.

Read all about Comic-Con 2012 in one convenient digest here.

I feel as if this should totally be used to make more Giant Snorses. I’d imagine ABS would be sturdier and take care of the problems with their necks. Though, I think there’d still be a bit of work to be done on the figure as these seem a little rough around the edges still.

Agreed and agreed. The only thing though is that giant = expensive. Think about the cost of this machine + materials with a max size of “loaf of bread”. You’d have to pay a lot more to make Giant Snorses. However, if the community chipped in, we could split the cost and make our own little Giant Snorse Factory Farm! Who’s with us?!

I’d be down for anything larger than the 3″ Snorse that I currently own (there’s no way I could talk myself into paying the secondhand prices of a Giant Snorse). Something the size of that Unicornasaurus (assuming it’s not shrunken) would be awesome! Of course I’m not saying individuals should just take up making copies of their favorite toys. I’d imagine with enough promotion/ work beforehand, if someone picked one up with the intention of being a manufacturer, it might be successful. Then again, I don’t know how much the plastic costs and obviously some time would be spent sanding each piece to make it smooth. And depending on those costs, resin might still be cheaper.

Thanks for the great post! I’ve been trying to figure out how to sell some of my 3d prints and the main issue is ultimately how long it takes to print. The material is totally inexpensive. I can realistically do 3 of the large Akashi a day, and that’s with the machine running all the time… Even with doing a really limited edition (say 30) I think it would be hard to get a collector to pay in the $60 to $100 range, which is what would make it worthwhile. Ugh. Any ideas would certainly be appreciated! Thanks again!

Intersting yours products

print 3d advertising products ans toys.